PURE TUNGSTEN WIRE

All our wire products are manufactured in Lewiston, Maine USA. With 90 years of wire production experience dating back to our history as part of Philips Lighting, Elmet is a trusted supplier to leading companies worldwide. Elmet’s tungsten and molybdenum wire are used in a variety of cutting-edge industries including aerospace, medical equipment and devices, university R&D, lighting, and high-temperature furnace.

PRODUCT DETAILS:

- Made in the USA and the only fully integrated US manufacturer of pure tungsten and molybdenum wire products

- Designed to exceed ASTM F288 specifications

- ISO 9001 and AS9100 certified manufacturing process

- Various finishes, lengths, and diameters available upon special order

WIRE IS AVAILABLE IS THE FOLLOWING MATERIALS:

- Mo (molybdenum wire) Diameter sizes range from below 0.001 inches to over 0.187 inches

- Mo-K also known as Moly HCT wire (potassium doped molybdenum wire)

- Mo-La (molybdenum lanthanum oxide doped wire)

- Mo-W also know as MB is an alloyed product of moly and tungsten (molybdenum-tungsten alloy – various compositions)

- W (tungsten)

- W-La (tungsten lanthanum oxide doped wire)

- W-K non-sag (potassium doped tungsten wire) W-K is wire which has been doped with trace amounts of potassium, causing the wire to exhibit an elongated interlocking grain structure with non-sag properties after re-crystallization. WK wire is produced in sizes from less than .001 up to .250 inches in diameter.

- Titanium Zirconium Molybdenum (TZM)

PURE Tungsten wire

| Typical Application | Description | Available Diameters | Tolerances |

| Support Wire | Cleaned | .003″ to .020″ | ± 3% wt |

| Support Wire | Cleaned | .020″ to .050 “ | ± 1.5% dia |

| Redraw Wire | Black | .001″ to .020″ | ± 3% wt |

| Redraw Wire | Black | .020″ to .060″ | ± 1.5% dia |

| Heating Elements | Cleaned | .001″ to .020″ | ± 3% wt |

| Heating Elements | Cleaned | .020″ to .250″ | ± 1.5% dia |

| Mandrel Wire | Cleaned | .004″ to .020″ | ± 1% to 3% wt |

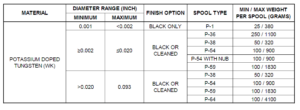

POTASSIUM DOPED TUNGSTEN (WK) WIRE

MB (MOLYBDENUM-TUNGSTEN ALLOYED) WIRE

| Typical Application | Description | Available Diameters | Tolerances |

| Aircraft and Automotive Windshield Defrosting | Special oxidized | <.001″ to .003″(also can be ordered by Wire resistance) | ± 3% wt |

| Other Varied applications | Cleaned | .003″ to .030″ | ± 3% wt |

Tungsten General Properties

Atomic Weight: 183.92

Density : 19.3 g/cc

Melting Point: 3410° C

Boiling Point: 5900° C

Coefficient of Linear Expansion at 20° C: 4.98 * 10-6/°C

Thermal Conductivity at 20° C :0.31 cal/sq cm/cm/sec/°C

Specific Heat at 20° C: 140 J/kg

Tungsten Wire Dimensions and Tolerances:

Wire diameters are generally expressed in terms of inches or mils (thousandths of an inch). For thin wires from .001 inches up to .020 inches in diameter, the diameter of the wire is measured by weight per unit length. That is, the weight expressed in mg of a 200 mm length of wire. The standard diameter tolerance is ± 3% of the weight measurement. Closer tolerances are available, depending upon the application for the wire product.

Tungsten Wire Tensile Strength:

Tensile strength for tungsten wire is usually expressed in grams per milligram weight of a 200 millimeter (or) g/mg/200 mm. The normal range of values is from 40 to 110 grams. In general, as tensile strength increases, wire straightness decreases.

Tungsten Wire Straightness:

Wire may be finished in the unstraightened or as drawn condition and is controlled to Elmet’s internal standards. Additionally, wire can be straightened via mechanical or heat treating processes. Typically, the measure of the straightness of tungsten wire is obtained by cutting a ten-inch long piece of wire and allowing it to lie on a flat clean surface. The maximum deviation from a straight line along its length is the quantitative measure of its straightness. In general, as the degree of straightness increases, tensile strength decreases.

Tungsten Wire Quality and Finish:

Tungsten wire is free of scratches, kinks, and distortions insofar as they are harmful to the intended end use of the product. Surface finish is supplied in the black, as drawn, condition, in which drawing lubricants and oxides are retained on the surface. It is also available in the cleaned condition which is accomplished through firing in hydrogen or electrochemical etching.

Tungsten Wire Spooling:

Wire is spooled on clean, defect-free spools. For very large diameters, tungsten wire is self-coiled. Spools are level filled without piling near flanges. Elmet ensures the outer end of the wire is properly marked and attached securely to the spool or self-coil.

About our Process:

When tungsten and molybdenum material characteristics and properties must be critically controlled for superior end product performance, consumers rely on Elmet Technologies’ unmatched expertise in the field of powder metallurgy. Our advanced powder processes to produce pure tungsten and molybdenum metal powders as well as specific metal alloys. By selectively influencing aspects of the metallurgical process, we can change characteristics like porosity, strength, and temperature resistance to meet our customers’ specific needs. At Elmet, our process is fully integrated and starts with the raw material, metal oxide, which is then purified to tungsten and molybdenum metal powder through a chemical reduction process. The powder is formed into semi-finished products through a series of advanced mixing, pressing, deformation and heating technologies. Finished products are then carefully manufactured to customer specifications utilizing our state-of-the-art machining and fabrication techniques.