Elmet Technologies, a global leader in the manufacture of high-performance tungsten and molybdenum components for the aerospace market, recently supplied parts for use in the Space Launch System (SLS) Rocket program, in the Orion Space Capsule. The Space Launch System (SLS) is the largest, most powerful rocket built so far. The first SLS mission (Artemis I) for the Artemis Program will be launched sometime in the next month or two. It will travel to the moon and return.

In the next mission (Artemis II), which will be manned space flight, astronauts will travel to the moon for the first time in 50 years.

The team at Elmet is proud of their accomplishments, meeting the requirements of the customer, and rising to the challenge for such a unique project. We are also honored to have participated in the SLS project, and we look forward to providing ongoing support for tungsten manufacturing and testing needs for the aerospace market. As we look forward to the SLS launch, we take pride in knowing Elmet Technologies ballast weights are in the Orion capsule. Our team is excited to follow the Artemis launch news, with an expected launch date of mid-November.

Aerospace Grade Tungsten & Molybdenum Components

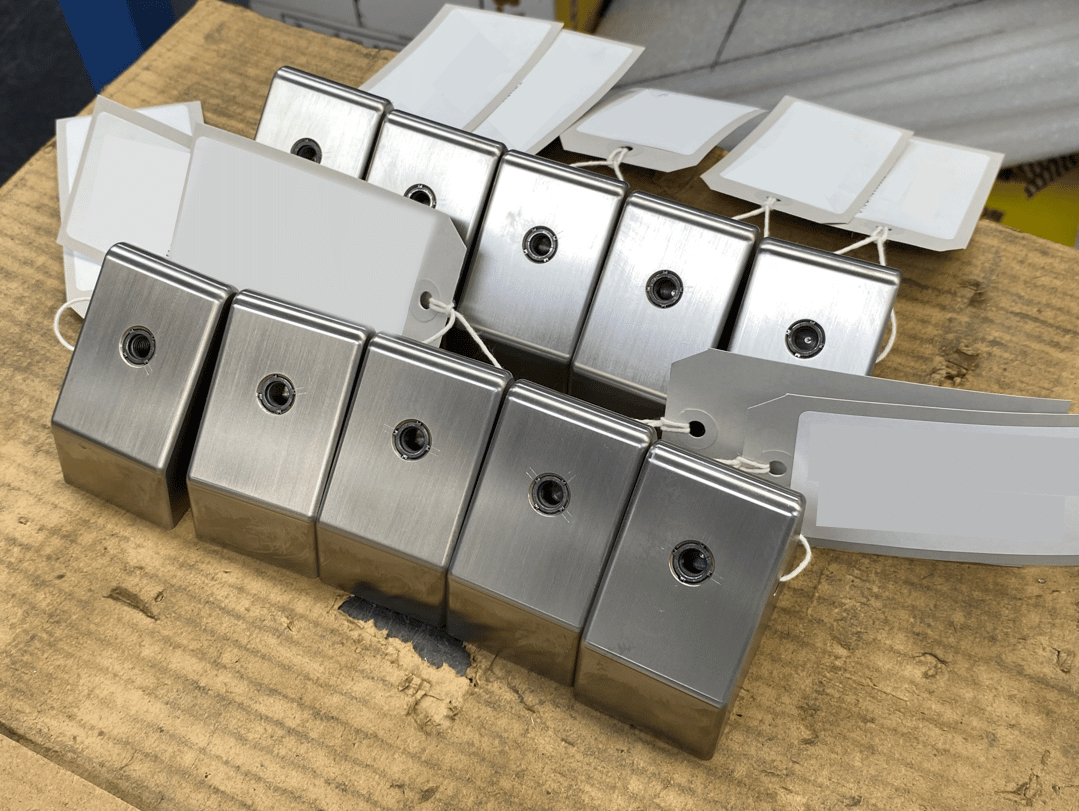

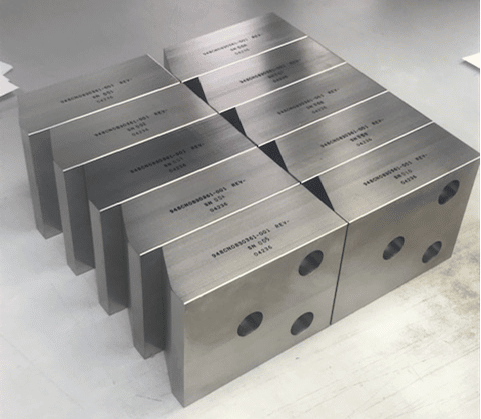

Specific to this program, Elmet manufactured aerospace-grade tungsten heavy alloy ballast weights used for the heatshield in the Orion capsule. Other programs involving Elmet Technologies components include Dragonfly, set to launch in 2026, and land on Titan in 2034 with Elmet molybdenum parts to play a key role in processing samples.

Elmet is involved in supplying several key tungsten heavy alloy products and processes to support ongoing aerospace projects. For this most recent project, Elmet’s involvement included:

- Manufacturing tungsten heavy alloy ballast weights used for the Heatshield.

- 7 different parts, with weights ranging from 7 to 33 lbs.

- Tungsten metal powder.

- This includes all pressing, sintering, and machining performed on-site in Lewiston.

- All lab testing for powder and final part mechanical properties performed by Elmet’s A2LA-accreditted lab.

- Each part ultrasonically tested for internal quality.

Elmet Technologies fully-integrated manufacturing, processing expertise, AS9100 certified quality systems, and in-house lab support the most stringent aerospace specifications and documentation requirements.

Elmet Technologies: Committed to the Aerospace Market

Over the past few years, Elmet has adapted to the needs of the aerospace market with new investments in tooling, technology, quality processes, and expanded its product portfolio to meet new material specifications and demands.

Elmet Technologies is proud of its team in supporting some of the aerospace industry’s most extraordinary programs to date. Through strict quality control procedures, our team ensured that all products meet the most stringent of specifications. The delivery of parts to this program is a significant achievement and demonstrates Elmet’s expertise in manufacturing tungsten heavy alloy products with mission-critical precision and accuracy.

Our team looks forward to following the progress, launch, and flight of the SLS Rocket, Orion Space Capsule, and other upcoming aerospace programs. As the dates get closer, we’ll be sure to follow the news and watch with excitement and pride.